Maybe You'd have been better off checking it before ....

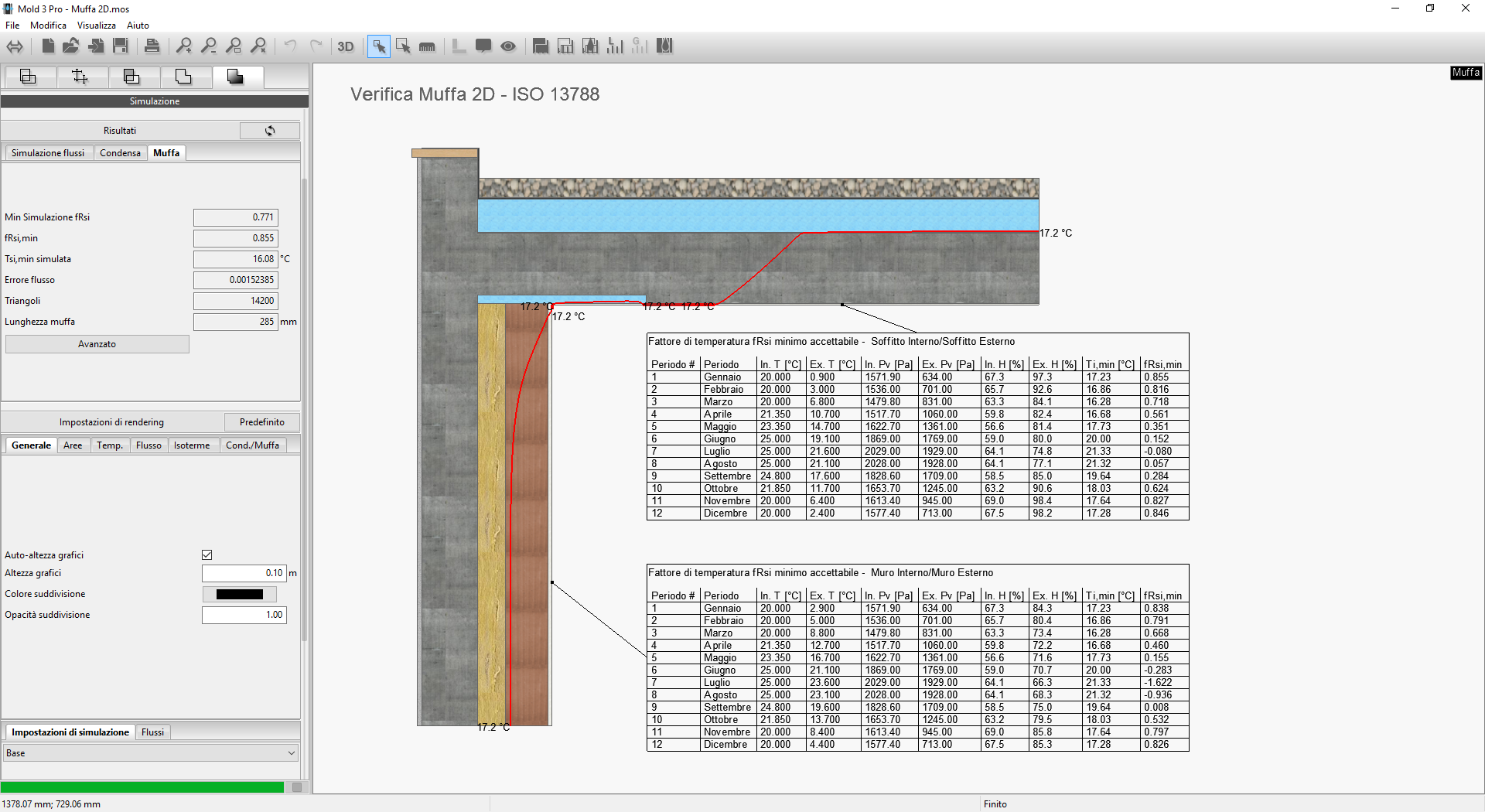

Mold simulation with Mold PRO 2D

Mold PRO performs mold verification according to EN ISO 13788:2013. Many think that it is enough to check the surface temperature in the coldest month, but they are wrong. Assessment should be done in the month with the highest acceptable minimum temperature factor, among those of the 12 months of the year. Mold PRO calculates all minimum acceptable fRsi values for all 12 months, for each boundary pair, and then shows mold formation on the surface in the worst situation.

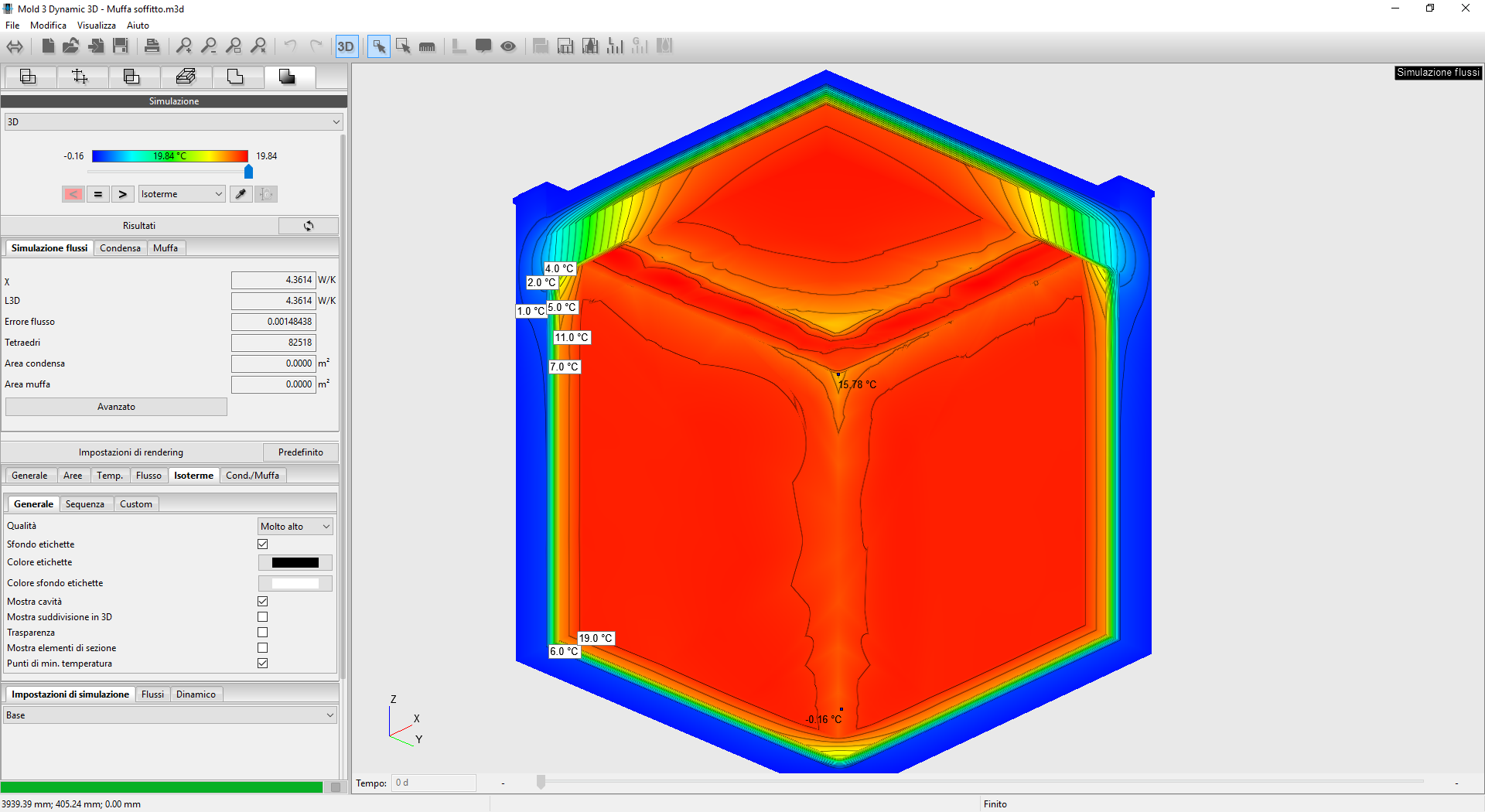

Mold simulation with Mold PRO 3D

In the case of contiguous thermal bridges, the traditional two-dimensional analysis does not give the real understanding of the actual surface temperature. Temperatures in an edge can be 2 or 3 or even more degrees lower than those detected with 2D analysis. Mold 3D allows you to quickly create three-dimensional models and analyze temperature across the entire modeled internal surface. This is particularly recommended in the case of mold assessment on complex or medium-isolated structures.

more accurate results with dynamic analysis

to know how heat is distributed in the structure at any given moment

watch the video

Mold assessment with Mold DYNAMIC 2D

With 2D thermal dynamic analysis you can assess the real temperature on the boundary based on climate data and the thermal inertia of the structure. Mold Dynamic performs fem simulations in successive moments, in the same way as movie frames, taking into account the temperature and humidity curves that can be loaded from external datasheets, as well as the specific heat and the volumetric mass of the materials. It is therefore possible to know the real temperature at each point of the section at any given moment.

watch the video

Mold assessment with Mold DYNAMIC 3D

Mold 3D Dynamic combines the benefits of three-dimensional analysis with thermal dynamic analysis. The program builds a temperature mapping at every point on the surface at any given moment. In this way, it is possible to assess with great precision the combined effect of contiguous thermal bridges and the change in the external climatic and internal thermoigrometric conditions. Mold Dynamic can also take into account radiation on the outer walls or internal radiant surfaces.

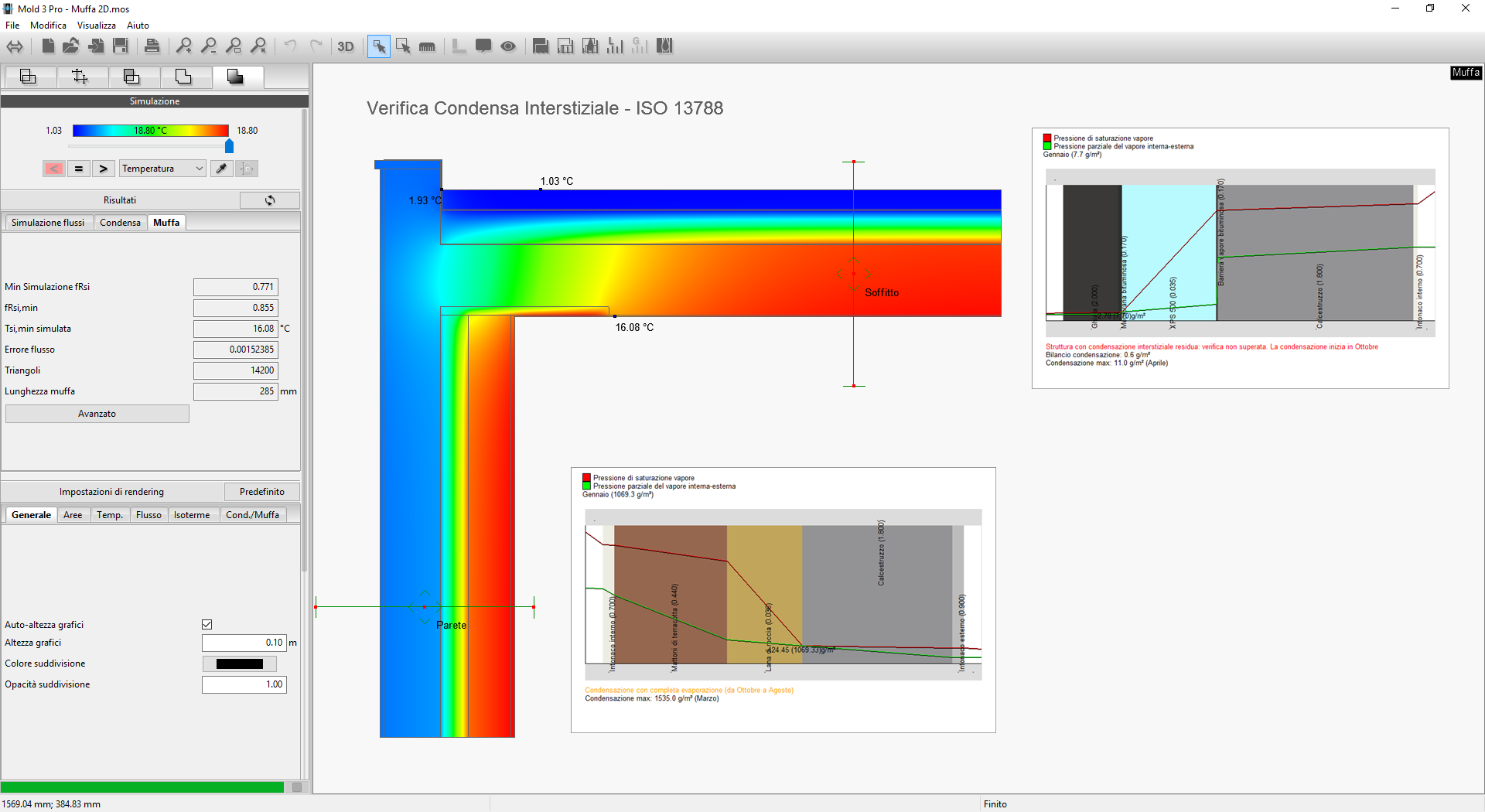

The calculation of interstitial condensation (Glaser)

interstitial condensation analysis according to UNI EN ISO 13788:2013

Interstitial condensation (stationary Glaser) with Mold PRO

With the same simulation, in addition to mold testing, Mold Simulator also tests Glaser for interstitial condensation, as provided by ISO 13788. The user can define the quantity and location of the section plans to be verified. For each plane, the amount of condensed and reevaporated steam is calculated, with both graphical and tabular display for each of the 12 months. It is also possible to obtain the temperature and thermal flow trend along the section floor.

watch the video

Interstitial condensation (Dynamic Glaser) with Mold DYNAMIC

Dynamic simulation allows you to perform the analysis of Glaser in variable regime according to the curves of the climate data and taking into account the thermal inertia of the structure. The program, through a subsequent series of simulations of the finished elements, calculates the real temperature at each point, taking into account the thermal inertia of the structure. In each of these moments, consider the possibility of steam condensing within each layer, based on the humidity values defined for that time. In the same moments, the possible accumulation of condensate and reevaporation is calculated, the accounting of which is therefore much more precise.